Pad Print Plates – Precision Etching

Best Practices for Reliable, Repeatable Pad Print Plate Etching

Why is Precision Pad Print Plate Etching Important?

Pad print plate etching accuracy is a key element in ensuring highly repeatable, quality pad print decoration. Access to precision-etched plates reduces both scrap and troubleshooting downtime. Trans Tech provides superior etching on both thick and thin steel pad printing plates.

Key Elements in Ensuring Precision Etching

Do you want to know the secret to our success in providing market-leading etching accuracy? It boils down to two key areas:

1. Control of the entire etching process and

2. Consistent investment in cutting-edge technologies

Control of the Entire Plate Etching Process & Investment in Cutting-Edge Technologies

For stand-out precision- Trans Tech ensures meticulous control over the entire print plate etching process.

For stand-out precision- Trans Tech ensures meticulous control over the entire print plate etching process.

With superior artwork expertise and careful plate material selection, we ensure each etched plate is cued for success from the beginning.

Next, we use cutting-edge technology to ensure unmatched precision in artwork placement and plate etch depth. Taken together, these last two steps allow us to provide stand-out repeatability.

To provide our customers with complete peace of mind, we issue a multi-point quality report with every etched plate we ship.

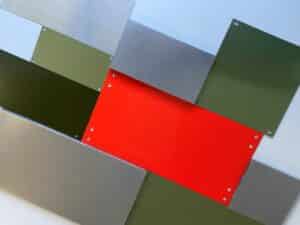

Pad printing plates are made out of either plastic polymers or steel. The two different types of plates differ in etching techniques, life span, and precision.

– Artwork Expertise

Experts in our Art Studio have an average of over 20 years of experience in turning your vision into quality pad-printed reality. We know how to get it right the first time – ensuring fewer problems on the production floor. It is key to find a partner with experience in areas such as finely detailed artwork and registration. Expertise in artwork requirements for specialty-depth, critical-line, and multi-depth etching is also key.

– Plate Materials

Our experts can then take your optimized artwork and set it up for precision etching. Quality end results require a quality start. So we make sure to start out with the highest quality blank pad print plates. We carefully identify materials perfectly suited for use in pad print plates. For example, we ensure the material used in our pad print plates is free of larger particles that can disrupt etching.

– Art Placement

Armed with quality artwork and a quality blank plate, Trans Tech can ensure precise digital artwork placement – as our proprietary etching process converts computerized digital artwork onto plates with market-leading precision. This, in turn, ensures highly repeatable image placement, image quality, and color.

Thanks to investment in cutting-edge direct-to-plate etching, images are applied to pad print plates with variation as little as plus or minus two-hundredths of an inch. This is more than twice as accurate than was previously possible!

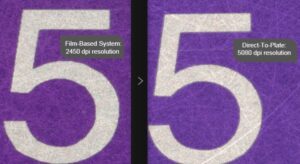

This same cutting-edge direct-to-plate technology not only greatly enhances art placement accuracy, it also enhances artwork resolution. Previously used film-based etching systems could often offer roughly 2450 dpi resolution. Our cutting-edge direct-to-plate technology provides twice the resolution – up to 5080 dpi.

– Etch Depth

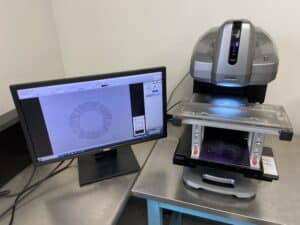

Investment in cutting-edge technology also allows Trans Tech to provide superior plate etch precision. Our Keyence Electronic Microscopes ensure etching with a market-leading variation of plus or minus 2 microns.

– Multi-Point Quality Report

Finally, we are so confident in the precision of our plates that we send a multi-point quality inspection report with each etched plate that we ship.

To summarize, we start out with unmatched artwork expertise and superior-quality plates. From there, we use cutting-edge technologies for precision artwork placement and etch depth. Finally, we send a full multi-point quality report with each etched plate.

This approach ensures not only that your current plate will precisely meet your production needs. It also ensures that each plate can be precisely replicated, so you can count on this quality time and time again.

Would you like to know more?

Please get in touch. We would love to hear from you.

Sigi Knappik is the Consumables & Quality Manager at ITW Trans Tech. During his 29 years working in the pad print industry, he has held a number of roles including purchasing, quality and operations management.

For stand-out precision- Trans Tech ensures meticulous control over the entire print plate etching process.

For stand-out precision- Trans Tech ensures meticulous control over the entire print plate etching process.