Supporting Products

Learn more about our supporting product range including pre- and post-treatment options, safety packages and accessories.

Trans Tech offers a wide range of ancillary equipment and engineered accessories to best fit your printing application needs. From anti-static pad blowers to drying and UV curing tunnel systems, Trans Tech has your printing process covered from start to finish.

Trans Tech has the expertise to prepare the surface of your substrate for optimal ink adhesion. We have a range of pre-treatment options including:

Flame Treatment

- Modifies product surface for ink adhesion.

- Fast & cost-effective.

- Great for automated applications.

Corona Treatment

- Modifies product surface for ink adhesion

- Safe & economical solution

- Small format – easily installed in automated line systems

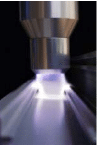

Plasma Treatment

- Modifies product surface for ink adhesion.

- Longest lasting treatment window.

- Powerful & small format for automated lines.

At Trans Tech, we have technologies designed to speed the ink drying process – ensuring durable print ready for packaging. We have a range of post-treatment options including:

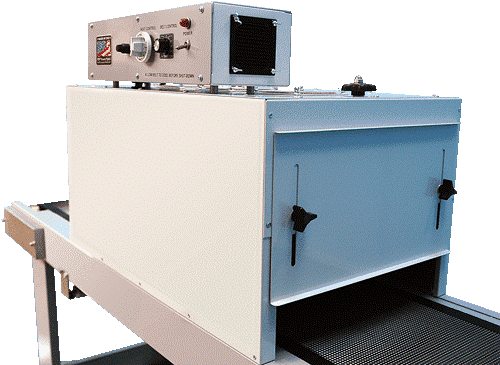

- Used for drying and curing a wide variety of inks

- Particularly well-suited for use with two-component inks using hardeners.

- Cost effective and simple controls

- Combination of direct radiant heat and air passing through the heat panel promotes rapid drying and minimizes production time

- Temperature range up to 220oF

- Used for curing inks at higher temps

- Digital controls and flexibility

- Speeds ink drying times allowing products to be handled and packaged quickly

- Temperature range up to 380oF

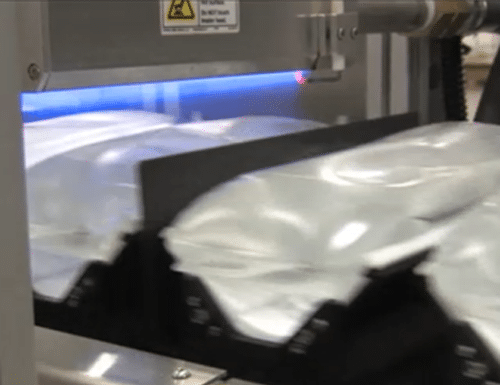

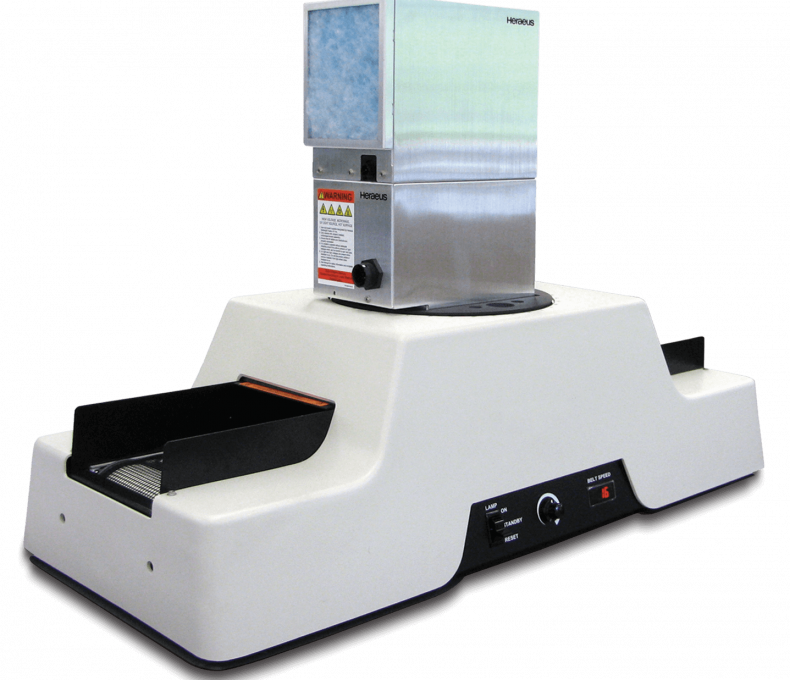

Ultraviolet curing is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives. Offering many advantages over traditional drying methods, UV curing has been shown to increase production speed, reduce reject rates, improve scratch and solvent resistance, and facilitate superior bonding.

- Ideal for small production parts

- Simple controls & small format

- Laboratory and R&D applications

- Testing of adhesives, inks, coatings

- Can be used in automated systems

- Substrates up to 7.5 in wide

- Effective curing width up to 6 in

- Internal exhaust blower assists with cooling

- Teflon® coated open-weave Kevlar® belt is for smooth performance, and treated to eliminate static charges

- Unique seam design provides uninterrupted belt surface

- Choice of 4 models and speed ranges from 2.0 to 250 feet/min (0.6 to 76 m/min).

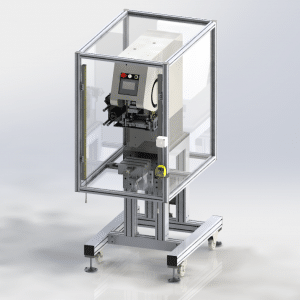

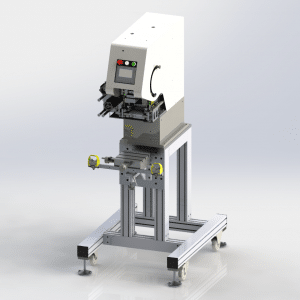

OSHA requires systems to prevent operators from reaching the point of operation when the machine is running. Trans Tech offers three standard safety packages for stand-alone operation of our standard pad printers.

| Safety Package Comparison | |||

| Covers | Operator Runs System By | System De-Energizes When | |

Full Guard Package |

Hard guarding covering the entire system and safety light curtains. | Using an external safety touch button. | Operator loads and unloads parts or when the operator interfaces with machine’s user interface. |

Small Guard Package |

Hard guarding covering the part handing area and safety light curtains. | Using an external safety touch button. | Operator loads and unloads parts. |

Two-hand Anti-Tie Down Package |

Package consists of two safety touch buttons. | Placing fingers from both hands on the safety touch buttons. | Operator removes a finger from one of the safety touch buttons. |

Anti-Static Pad Blowers

- Static & ink consistency control

- Improves ink transfer

- Not a good option for ink that is “thick and tacky”

Magnetic Pad Blowers

- Assists with transfer of ink from pad to part

- Especially helpful in high speed applications

Plate Etching Exposure Unit

- Uniform light distribution

- Powerful vacuum

- Highest quality etched plates with the finest precision

We have a large variety of additional supporting technologies. If you don’t see what you need on the list below- give us a call. Odds are very good that we have what you are looking for.