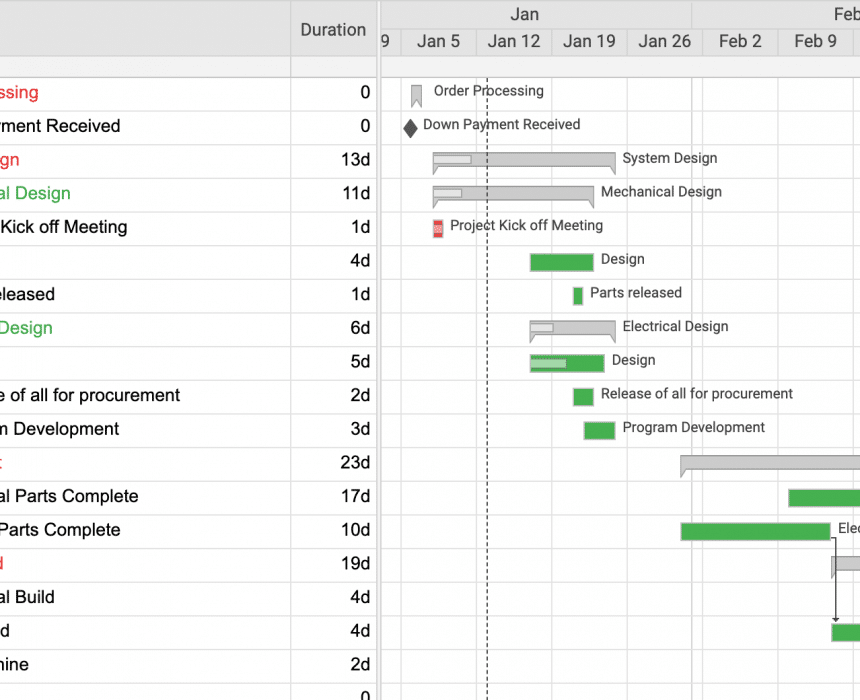

Trans Tech’s robust project management goes beyond the standard steps you may be familiar with – system design, procurement, build, debug, factory acceptance testing, and customer sign off.

Our process also ensures three key foundational goals are achieved: