Industry Challenges: We understand the challenges commonly associated with electrical component decoration.

Trans Tech’s customer or technical support staff can provide insight into the following key areas:

- How to create systems flexible enough to cover a wide variety of different electrical component applications – including two-color print in two layers.

- Ink failure – typically in adhesion or wearability testing.

- How to adjust pad printing settings to adapt to the production environment – temperature, humidity, etc.

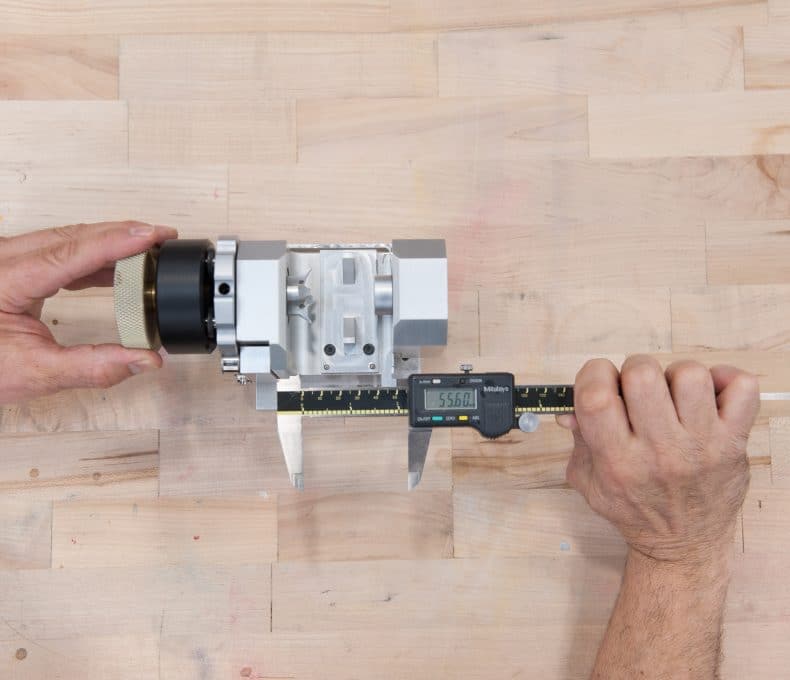

- How to develop high precision automation systems for maximum efficiency and productivity.