Pad Print Engineering Expertise For Superior Pad Printer Design

Your pad printer design solution expertly built

Market-Leading Expertise Meets Cutting Edge Technology

Once you have a system carefully designed for optimal performance for your application, our mechanical and controls engineers and machine-building experts are ready to build your system.

Market Leading Engineering Expertise

Our engineers have an average of 15 years of automation experience to design your pad printing system with market-leading precision. You will see their stand out expertise in every phase of the system development including:

- Pad Printer Selection/Creation

- Control Selection (your preferred control brand)

- Custom Fixture and Tooling Design

- Bulk Loading and Unloading

- Optical and Laser Sensing/Positioning

- Pre-treatments (corona, plasma, flame)

- Robotic Product Placement / Dial Tables / Linear Slides

- Post-treatments (drying tunnels, UV curing)

- Vision Systems

- Quality Qualification – Testing & Documentation

Cutting Edge Technology

For decades, Trans Tech has invested in cutting-edge tools that allow us to produce pad printing solutions with unrivaled precision. Often, we are the only company in the market to provide access to high-precision tools.

Laser Pad Base Cutter

- First-in-the-industry -innovative laser cutter for wood pad base manufacturing.

- Speed pad base production by as much as 40%.

- Unparalleled precision cutting of pad bases ensuring there is no variation from base to base.

Digital Silicone Mixer

- First-in-the-industry – an innovative digital system that quickly meters and mixes silicone for unprecedented accuracy in silicone formulation for printing pads

- Ensure that pad’s silicone formulation is precisely metered to ensure a highly repeatable decoration

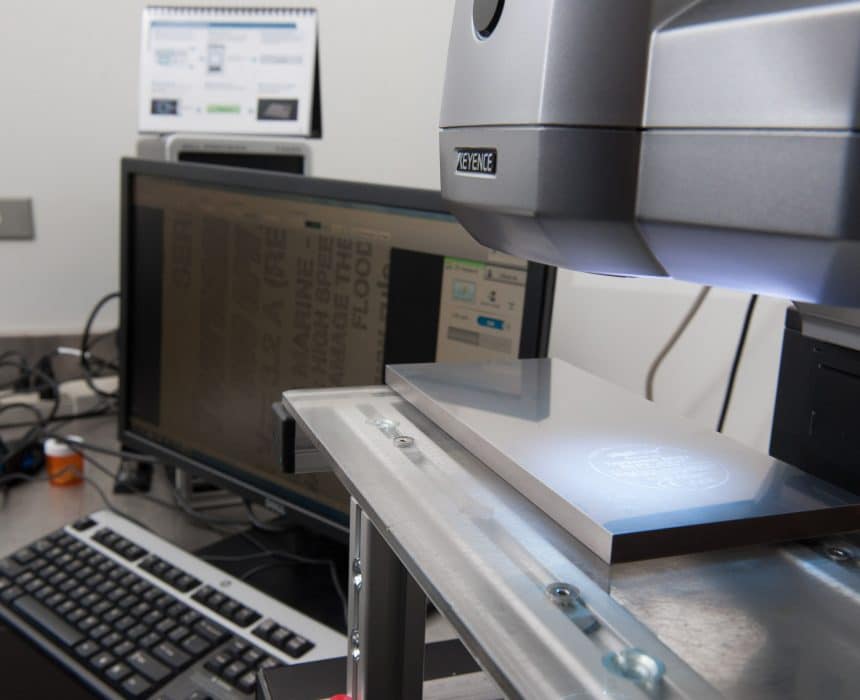

Keyence Electronic Microscope

- Ensures accuracy of plate depth to +/- 2 microns.

- Detailed control certificates.

- Ensures precision etching and superior repeatability from plate to plate.

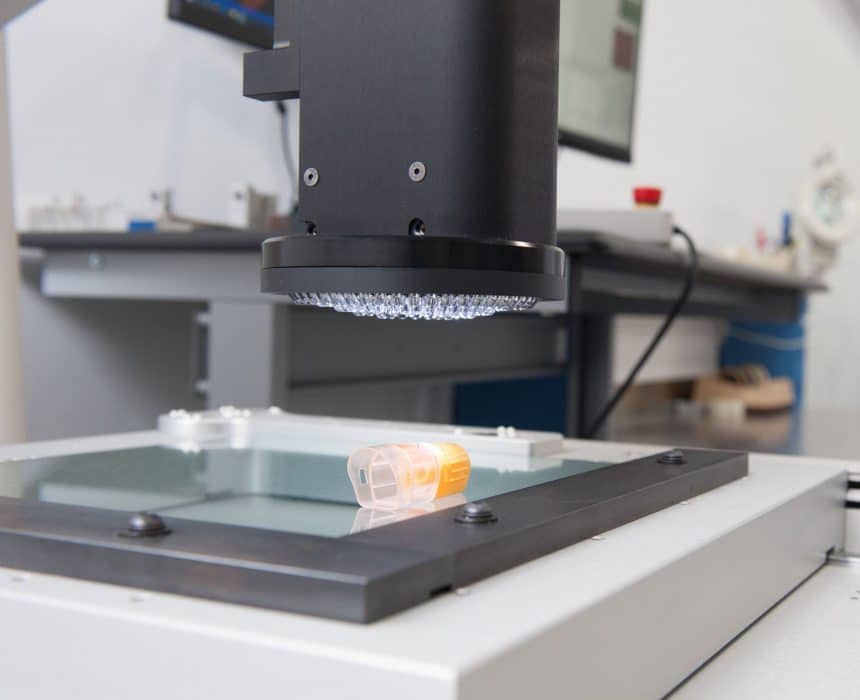

MicroVu Vertex

- Vision system that determines the accurate location of graphics on the parts and makes part drawings.

- Software provides accurate & quick dimensional measurements.

- Can be utilized to import CAD models, write inspection programs, calculate GD&T and provide data to export into a .DXF file.

- Encoder resolution of 0.1 Micron

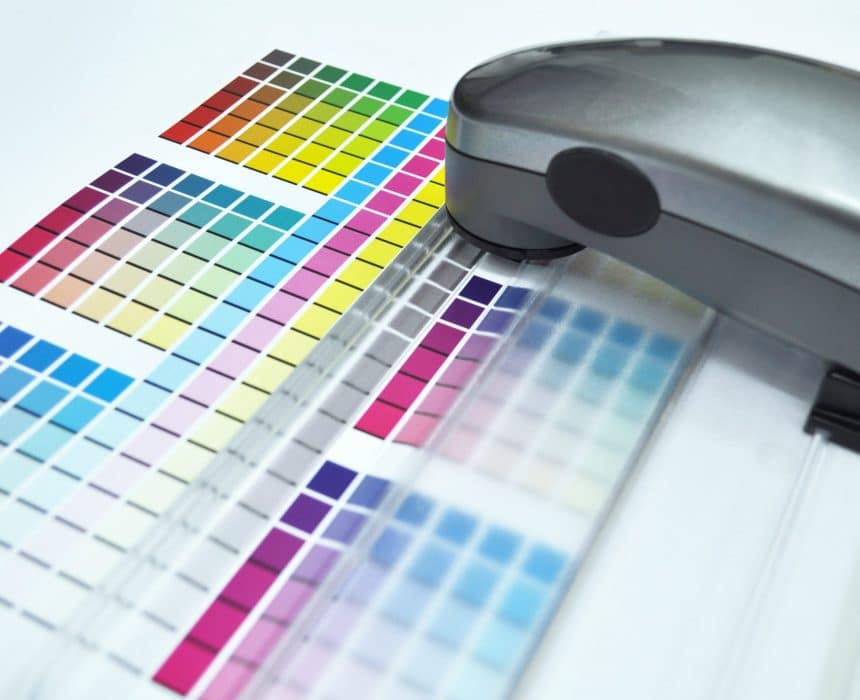

Spectrophotometer

- Ink mixing – X-Rite spectrophotometers ensure customers receive precise color performance batch after batch with computerized accuracy.

Precision Color Matching

- Each ink color batch controlled within a ΔE of 2.0 or less.

- Ensures our ink shades are highly accurate and repeatable year after year.

Engineering Team

(630) 752-4000

We know how to use market-leading expertise and innovative high-precision tools to build systems ready for highly repeatable performance.

How can we help you?