Pad Print Plates – The Basics

What are pad print plates? What types of pad print clichés are available?

What are pad print plates?

A pad print plate, or pad printing cliché, is a flat metal or plastic plate that is used in the pad print decoration process.

Pad print decoration involves transferring an image from an etched plate to a product using a silicone pad. The pad printing plate is etched with the desired image or text, and ink is applied to this etched surface. When the silicone ink pad presses down on the plate, the ink is transferred to the pad, which stamps the image onto the product or component being decorated.

Why are pad printing plates important?

The pad printing plate is an important element in the pad printing process, as it determines the quality and accuracy of the printed image.

The quality of the plate depends on a number of factors, including the image’s resolution, the etching’s depth, and the type of material used for the plate.

What types of pad print plates are available?

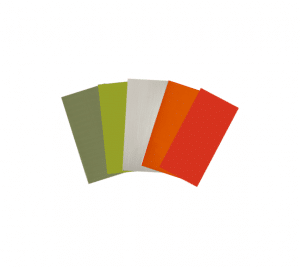

Pad printing plates are made out of either plastic polymers or steel. The two different types of plates differ in etching techniques, life span, and precision.

Plastic Pad Printing Plates

Steel Pad Printing Plates

Precision Etching for Pad Print Plates

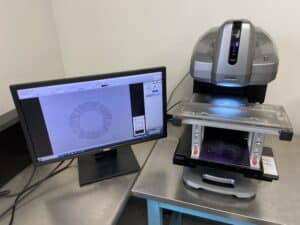

Trans Tech provides both blank as well as fully-etched pad printing plates. We also provide etching equipment.

Frequently, plastic plates are sold blank to be etched by our customers in-house, whereas steel plates are etched at Trans Tech prior to shipping.

Plastic pad print plates are typically etched with either an alcohol or water wash. Some plastic plates are compatible with CO2 laser engraving. Both thick and thin steel plates are laser etched.

Etching Accuracy

Etching accuracy is a key element in ensuring highly repeatable, quality pad print decoration. When selecting a pad printing plate – it is key to find a partner with experience in areas such as finely detailed artwork and registration. Expertise in specialty-depth, critical-line, and multi-depth etching is also key.

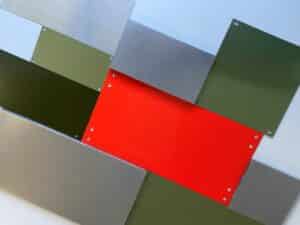

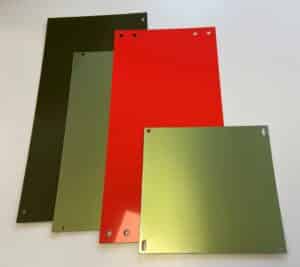

Pad Print Plate Sizes

Pad printing plates are available in both standard and custom sizes. At Trans Tech, our standard sizes for pad printing plates are

70 by 140 mm

90 by 165 mm

100 by 215 mm and

150 by 300 mm

We also offer custom-sized plates ranging from smaller 60 x 60 mm plates up to plates as large as 1000mm in length (for these larger plates the maximum exposure area is 900 mm by 610 mm.

Pad printing plates can be sent with Universal Configuration or punched holes that allow the plates to be used on Trans Tech or competitor pad print equipment.

Would you like to know more?

Please get in touch. We would love to hear from you.

Sigi Knappik is the Consumables & Quality Manager at ITW Trans Tech. During his 29 years working in the pad print industry, he has held a number of roles including purchasing, quality and operations management.