Industry Challenges: We understand the challenges facing medical companies. Trans Tech’s customer or technical support staff can provide insight into the following key areas:

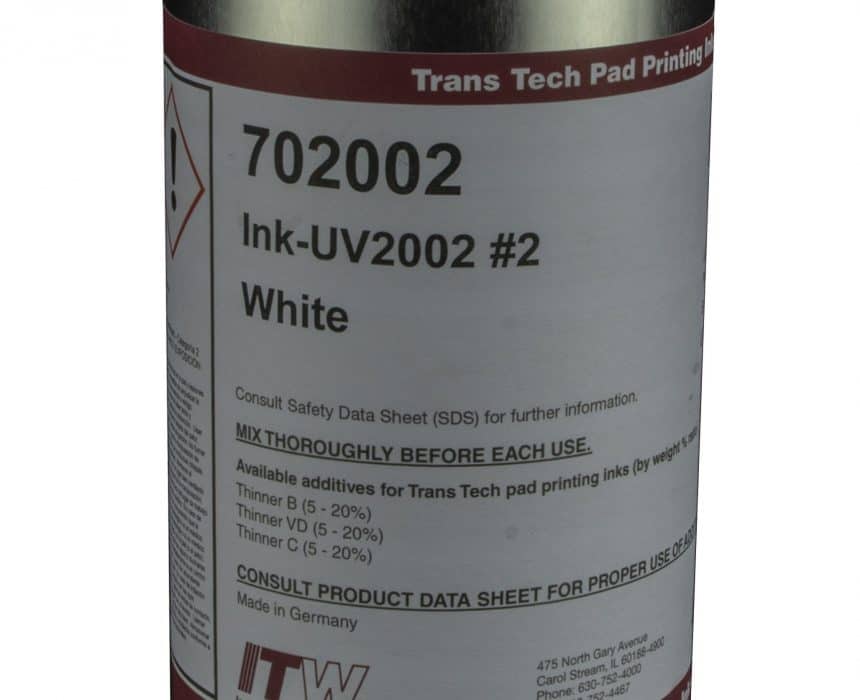

- Given the extremely rigorous validation process, our medical products must go through – we can ensure we get product decoration right the first time.

- We can ensure decoration technology is robust and durable enough to provide superior performance for years and years to come (so as to not have to repeat the extremely rigorous validation process a few years down the road).

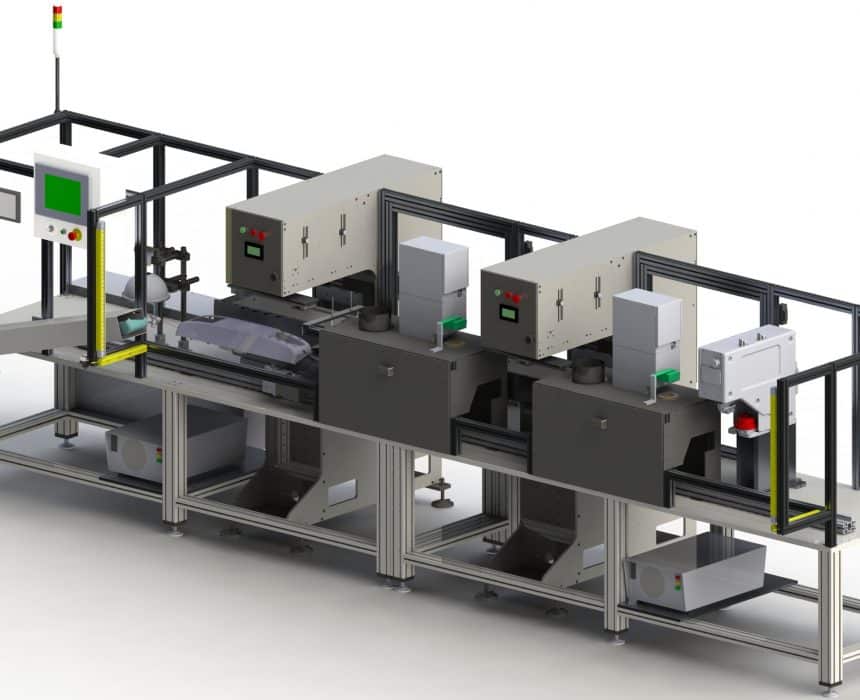

- Given the pressure to reduce labor costs- we can cost-effectively integrate automation into your product decoration process.

- We ensure quick turn over and flexibility in product decoration technology for customers who produce a number of different medical devices or components.

- We can provide reduced floor space or cleanroom compatible product decoration solutions.