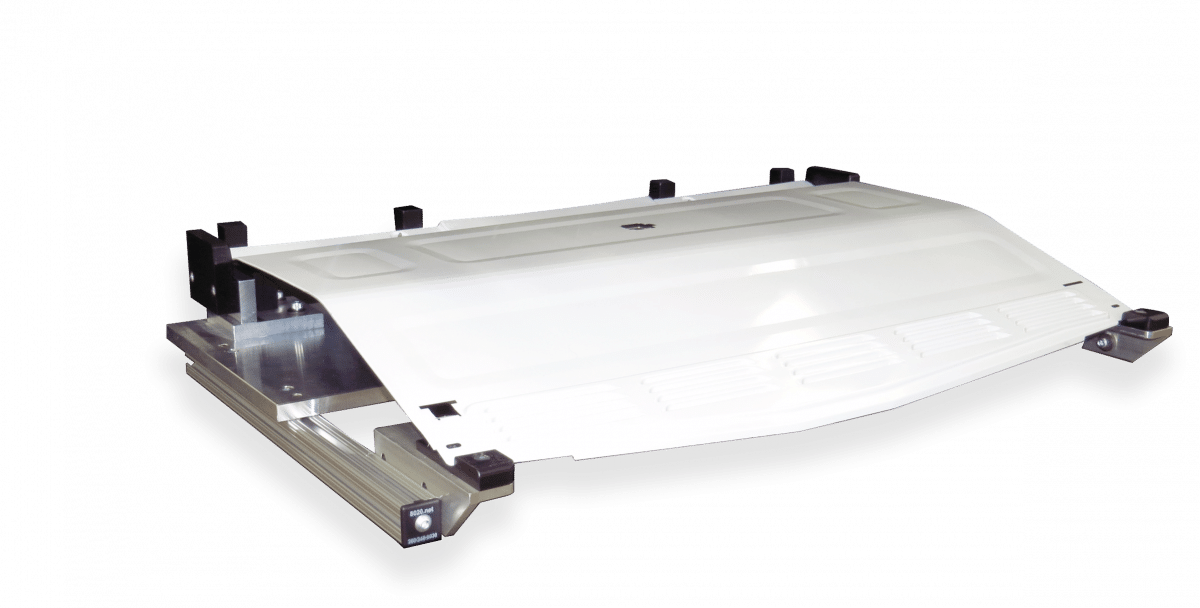

Precision Pad Printing Holding Fixtures: Ensure Stability and Accuracy

Superior Performance & Ease

The Foundation of Repeatable Decoration

Highly repeatable product decoration starts at the holding fixtures. If your part is not held securely at precisely the right angle, it is not possible to achieve quality, repeatable decoration.

Trans Tech’s dedicated team of fixture experts have decades of experience in creating precision fixtures – painstakingly designed for optimal performance in your unique application.

Unique Solution

Together at last... Precision Placement & User-Friendliness

Features

Error Proof Design

- We carefully design our fixtures so that they work only in one way – ensuring precise product positioning time and time again.

- Our customers are so happy with the results – they actually came up with the descriptor “error-proof” for our fixtures!

2 Step "Load & Lock"

- Our fixtures feature an easy 2 Step “Load and Lock” process where rollers, push pins or simple clamps are used to ensure operator-friendly performance combining precision alignment, firm hold, and quick loading and unloading.

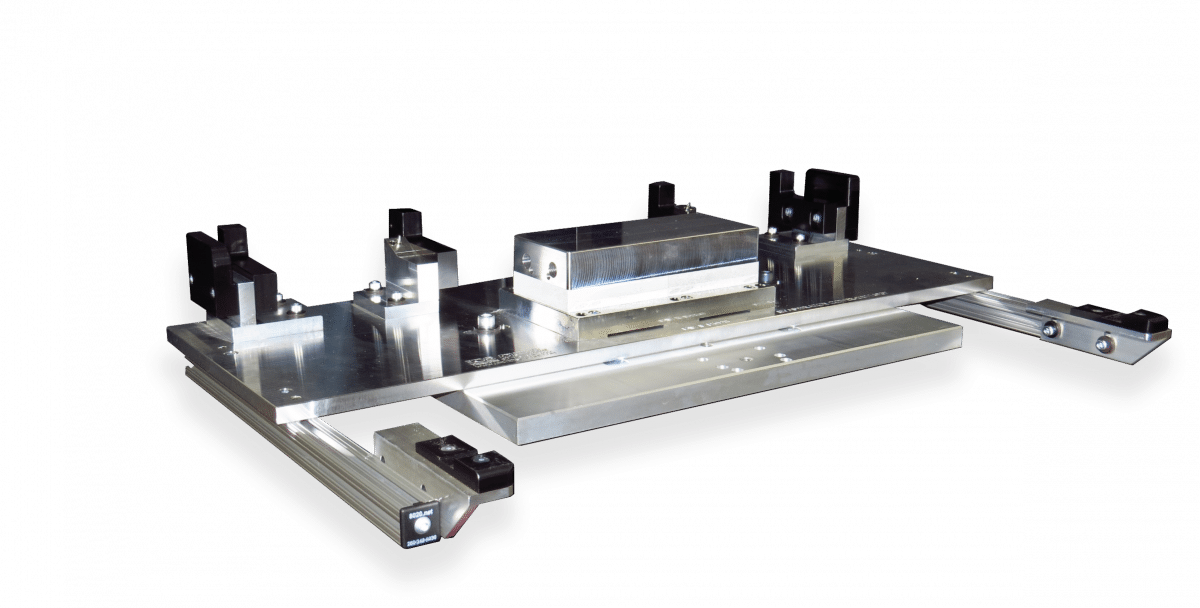

Types of Fixtures

We have a fixture for YOUR application!

At Trans Tech, we provide a wide range of different types of fixtures for an ever-bigger range of different applications. Our highly skilled fixture team can custom build a fixture to meet the precise needs of your application.

We Design Fixtures For

- Trans Tech equipment

- Competitor equipment

- Manual lines

- Automated lines

Fixture Types

- Standard

- Multi-position

- Vacuum Hold Down

- Automatic Rotate

- Manual Rotate

Substrates

- Anodized Aluminum

- Wet Teflon Seal (medical grade)

- Derlin (medical grade)

- Stainless Steel

Special Considerations

We´ve Got You Covered

To identify precisely the best holding fixture for your unique application, Trans Tech experts consider a wide array of factors including:

- Substrate to be decorated

- Scratch resistance requirements

- Industry-specific requirements (medical grade, etc)

- Compatibility with pre-and post-treatments

- Number of colors required

- Board shuttle type

- Artwork requirements- distortion

- Pad placement and composition

- Part height requirements

- Pad printer capabilities

Holding Fixture Team

(630) 752-4000

We have decades of experience in creating fixtures – meticulously designed for optimal performance in your application.

How can we help you?