Pad Printing Plates (Clichés)

Learn more about key printing plate selection criteria as well as about our wide range of printing plates and supporting supplies.

Trans Tech is proud of our reputation as the industry leader in pad printing plate making. We provide etched plates (with market-leading precision), blank plates, and plate etching supplies. They are available in standard and custom sizes in universal format (punch holes for use in any system). Each etched plate also comes with a quality report showing etch depth accuracy.

Our knowledgeable plate team (with 100+ years of combined experience working with art and plate(s) for pad printing) is ready to help you identify the best printing plate for your specific application.

Trans Tech offers a wide range of plastic, laser, thick steel, and thin steel foil printing plates to fit the full spectrum of pad printing applications. Each plate material type has features and benefits that make it suitable for specific requirements and operational budgets.

Thick Steel Plates (10mm)

- Up to a million impressions

- Most durable and resistant option

- Highest precision image

- Critical image alignment for high tolerance applications

- Etched at Trans Tech

Thin Steel Foil Plate

- 150,000 impressions

- Critical image alignment for high tolerance applications

- Crisp, clean lines

- Etched at Trans Tech

Red Polymer Plates

- 100,000 impressions

- Highest quality print and longevity of all plastic plates

- Alcohol wash

- Red color

- Variable depth

Starlight Laser Plates

- 20,000 impressions

- CO2 laser Compatibility

- Green color

- Variable depth

H2 Orange Plates

- 15,000 impressions

- Finer detail due to smaller particles in plate

- Water Washout

- Orange color

- Variable depth

Our designated plate making team has over 100 years combined experience in pad printing. We know how to carefully study all relevant factors in order to recommend the printing plate that best fits your specific needs.

Specifically- we look at:

- Plate performance requirements

- Application requirements (substrate and geometry)

- Artwork requirements

- System requirements

- Etch depth

- Artwork positioning on printing plate

- Print speeds

- Print volume

- Selected ink type

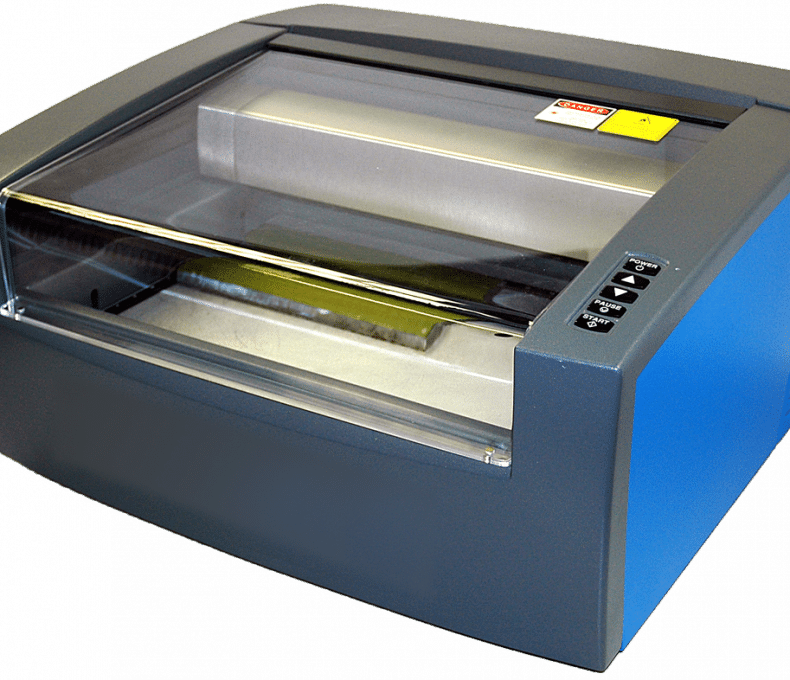

In addition, Trans Tech provides a number of supporting technologies for customers who wish to produce their own.

- StarLight LPM computer-to-plate, laser plate etcher

- Trans Tech Exposure Unit

- 21-Step Grey Scale Test Kit

- Plate Washout Tray and Supplies

Plate making instructions can be found in our Info Center

Simple, Functional Design

Enables rapid creation of laser plates for short and long run jobs within pre-set parameters of solid, screened, and four-color process.

User-Friendly Input

Easy-to-use software makes importing of graphics and positioning of images on the plate visible and intuitive with minimal learning curve required.