Pad Print Decoration on Medical Products

Market-Leading Precision & Efficiency

Pad Print Decoration on Medical Products

It is common to find pad print decoration on medical products. This is because pad printing is well-suited to provide the highly repeatable, highly precise decoration that medical brands and their suppliers require.

What is pad print decoration?

Pad Printing is a product decorating process that transfers single or multi-color 2-dimensional images onto nearly any 3-dimensional object. The pad printing process utilizes a silicone ink cup to transfer ink onto a printing plate. When the ink dries, the resulting decoration is exceptionally durable. Pad Printing provides precise decoration that is durable and highly repeatable for mass production.

What types of information are often applied to medical devices and components?

Pad Printing is often used to apply

-branding

-functional deposition

-identification marking purposes

What pad print decoration requirements are essential for the medical industry?

Like in most markets, medical companies require repeatable, high-quality decoration. Due to the nature of medical devices, medical brands and the OEMs and suppliers that support them often also require extreme decoration precision, compliance support, and superior print durability. Because of the rigorous nature of approval processes, they also need highly durable decoration equipment (to avoid having to repeat the approval process with new machinery)

What kind of experience does Trans Tech have with pad printing for medical devices and components?

For over 40 years, Trans Tech has provided quality decorating solutions to leading brand owners, component/contract manufacturers, and small molders. We provide:

- Precision Image Quality (standard tolerance +/-0.005”).

- Documentation and Validation Support (URS, FS, IQ, OQ, PQ).

- Total Process Support (systems, consumables, pre-treatment, and post-treatment equipment).

- Full Automation Support (partial to full turn-key solutions, including integrated vision systems).

What types of medical devices and components are well-suited for pad print decoration?

Pad printing is well-suited to a wide range of medical devices and components. In particular, pad printing is often used to decorate:

- Medical Devices & Components

- Housings

- Measurement Wheels & Disks

- Syringes

- Standard disposable syringes.

- Pre-filled syringes.

- Safety syringes.

- Auto injection devices.

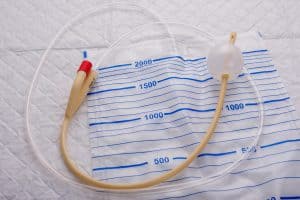

- Catheters & Medical Tubing

- 6 French to 22 French diameter

- Dosages Wheels

- Air Disk Wheels

- Cylinder Wheels

What specific pad print machines, supplies, and services does Trans Tech supply for medical product decoration?

Trans Tech provides everything a medical brand or medical market supplier needs, from concept support to completed product handling. We have a wide range of systems, supplies, and services uniquely tailored to support medical products.

What types of pad printing equipment does Trans Tech offer to medical brands, their OEMs, and suppliers?

We have a wide range of pad printing equipment and the expertise to identify the best solution for your unique application. We offer both electromechanical and pneumatic systems as well as rotary solutions. Both stand-alone and fully automated formats and single and multi-color formats are available. We also provide a range of pre-and post- treatments when applicable.

What types of pad printing supplies/consumables does Trans Tech offer to medical brands and their OEMs?

Trans Tech provides turn-key solutions- including pad printing supplies carefully designed for optimal performance and efficiency. We offer customized fixtures and tooling. We offer both standard and customized pad printing plates, ink cups, and pads. Trans Tech also provides an extensive range of cleaning supplies tested for optimal performance with pad printing applications.

What types of services does Trans Tech offer to medical brands and their OEMs?

Trans Tech supports our medical customers from project concept through installation and beyond. Our services include optimal solution identification, art development, custom supplies, and superior technical support and training.

Does Trans Tech offer any unique products/services specially designed for the medical market?

Trans Tech has over 40 years of experience working closely with medical brands and their suppliers. We have a wide range of specialized skills and products for this market, including knowledge of clean-room compatible environments and medical class VI inks.

Would you like to know more?

Please get in touch. We would love to hear from you.

Chris Demell, Global Medical Market Manager at Trans Tech, has over 15 years of pad print experience. Chris uses his deep expertise in the specific requirements of key markets to help companies find precisely the right pad print equipment for their unique project.