High Speed Rotary Pad Printer from Trans Tech

Unique-In-The-Market: High Speed, High Precision, Highly Repeatable Syringe Decoration

What is unique about the Trans Tech High Speed Rotary Pad Printer?

What types of products or components does this machine decorate?

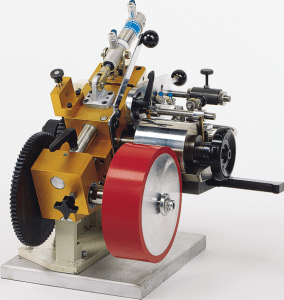

Unique in the industry, the Trans Tech Single-Head Rotary Gravure Pad Printer provides superior precision decoration on cylindrical, round, oval, or conical-shaped parts at speeds up to 9x faster than standard high-speed pad printers.

It is the fastest, most-accurate rotary pad print system available in the market today.

Our Rotary Pad Printer is ideal for printing:

- Up to 360° on round, oval, or conical-shaped objects (≤4-inch diameter)

- Images up to 12″ by 11″ on flat surfaces.

What speeds are achievable when using the Trans Tech High Speed Rotary Pad Printer machine to decorate syringes?

The Trans Tech RTI Rotary Pad Print machine is exceptionally well-suited to applying decoration on syringes ranging from 1ML- 60ML in size. Speeds of 500 to 600 pieces per minute are possible.

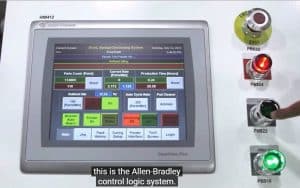

What type of controller does the Trans Tech RTI Rotary Pad Printer use? What are its benefits?

The Allen-Bradley controller provides several key benefits. With this controller, operators have a range of helpful information at their fingertips, including live part counts and production hours. One key feature of this controller is that it allows for password protection. With password protection- it is possible for operators to get in to use precisely the features they need while more advanced features are available for maintenance teams or super admins.

What kind of loading system is compatible with the Trans Tech RTI Rotary Pad Printer machine?

Feeding can be done either via a hopper feeder or from overhead via continuous feed.

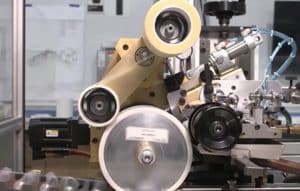

What happens when the syringes enter the bowl?

From the feeder, parts come into a bowl where they are aligned and fed into a walking arm that takes them to the transition wheel.

What unique feature allows the RTI Rotary Printer to enhance efficiency?

The RTI Rotary Pad Print machine provides a unique “Short Shot Detection System” in the transition wheel. This allows operators to identify any short shot early before it can advance further down the line and cause a backup. This Short Shot detection system avoids costly machine jams and downtime and resulting product scrap that result.

Scrap is also reduced thanks to dynamic auto-speed adjustments with a servo drive. When the volume of parts feeding into the machine is reduced, the printer automatically adjusts by reducing its speed rather than stopping altogether.

How else does the RTI Rotary Pad Printer minimize downtime and enhance efficiency?

Automatic Ink Replenishment

The system features an automatic ink replenishment system that ensures no downtime is needed to maintain ink viscosity, eliminating the need for an operator to mix ink manually. An ink pump optimizes viscosity and re-circulates ink. This optimizes viscosity by mixing the optimal amount of thinner into ink.

Tape Off System

The integrated tape-off system allows printing pads to be cleaned without stopping the machine.

Are there any features designed to be efficient during maintenance?

Yes! There are many. Here are a few:

- Lever-operated quick-drop ink tray with a detent locking device for spill-free removal

- Cliché drum hand wheel for easy cliché drum removal from the printer shaft

- Tilt-up doctoring assembly device for tool-less removal of the doctor blade from the cliché drum

How durable is the RTI Rotary Pad Printer machine?

Many RTI rotary pad printing machines have been running for decades, and the system is known for providing industry-leading durability. The increased doctor blade and drum life are achieved by replacing the set wear pattern common to older mechanical systems with reciprocating doctor blade assembly and random motion, independent of drum rotation.

Summary

The RTI Rotary Pad Printer from Trans Tech provides market-leading precision, repeatability, and efficiency at speeds up to 9x faster than those achieved by traditional pad print decoration. This system is an excellent choice for high-quality decoration of syringes.

Would you like to know more?

Please get in touch. We would love to hear from you.

Chris Demell, Global Medical Market Manager at Trans Tech, has over 15 years of pad print experience. Chris uses his deep expertise in the specific requirements of key markets to help companies find precisely the right pad print equipment for their unique project.