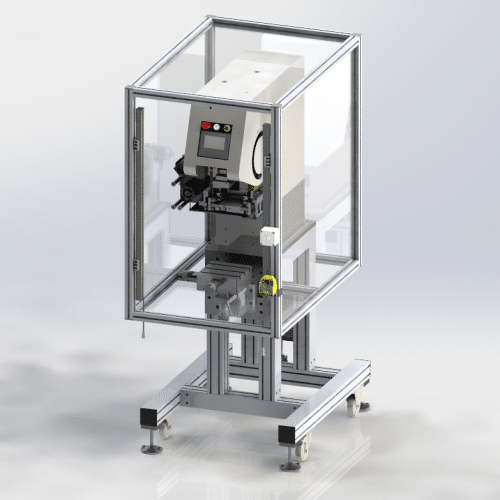

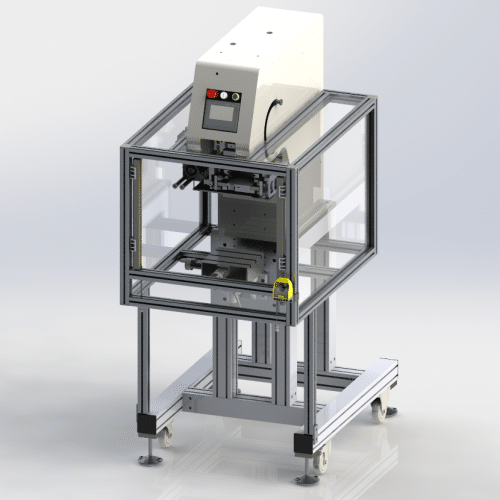

SealCup Express

The Durability You Love, Now with Market-Leading Time and Cost Savings

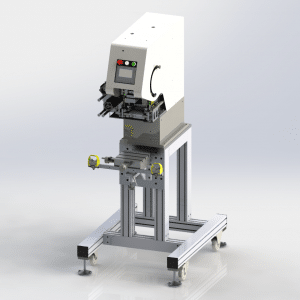

The original SealCup Express pad printer was renowned worldwide for its durability and reliability at high speed.

Patented, innovative new features allow the new SealCup Express to combine industry-leading durability and reliability with unprecedented time and cost savings.

The best features from leading North American (Trans Tech) and German (Morlock) pad printers have been brought together to bring a beloved industry favorite back with a bang.

The Durability You Love, Now with Market-Leading Time and Cost Savings

The original SealCup Express pad printer was renowned worldwide for its durability and reliability at high speed.

Patented, innovative new features allow the new SealCup Express to combine industry-leading durability and reliability with unprecedented time and cost savings.

The best features from leading North American (Trans Tech) and German (Morlock) pad printers have been brought together to bring a beloved industry favorite back with a bang.

Features

Industry Leading Reliability

Up to 30% less downtime than alternative pad printersSolid industrial construction & smart German design.

Industry Leading Durability

Lasts up to 50% longer than alternative systemsIndustrial construction & thick steel clichés.

Significant Cost Savings

Reduce labor time and cleaning supplies with up to 27% cost savingsTool-less SpaceFrameTM with disposable ExpressLinersTM replaces conventional ink cups.

Unprecedented Time Savings

Pad changes up to 80% faster & ink changes up to 86% fasterTool-less pad changes, super-fast ink changes, and built-in pad cleaners result in time savings compared to alternative pad printers.

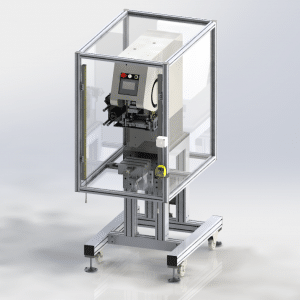

Integrated Safety Features

CE-Compliant Controls & System DesignDesigned from the ground up with CE components and integrated safety modules that interface with safety guard packages.

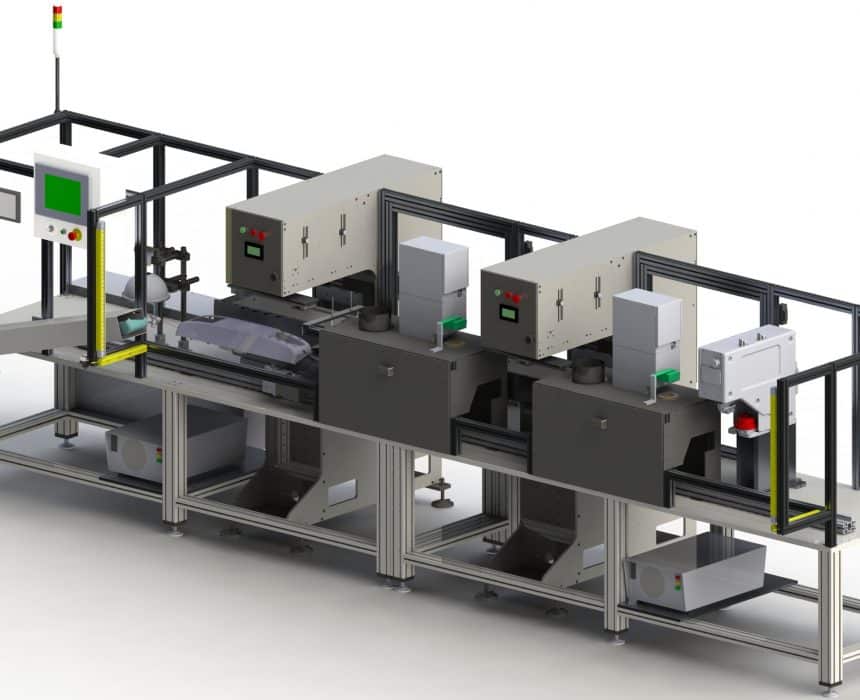

Modular Architecture

No additional controls systems necessaryDesigned to integrate with multi-position fixtures, dial tables, linear slides, and other printers for semi-automated operation.

High Impact Decoration

2-Color OptionTwo-color decoration in a single electromechanical system.

Real Estate Savings

Right- and Left-Hand Design OptionsTwo pad printers can print side by side in reduced space- reducing the number of stations by 2 on a dial system or decreasing the length of a linear system by 155 mm.

| Technical Specifications | |

| Cycle Speed | Up to 3600 cycles/hour |

| Drive | Electromechanical |

| Max Pad Compression | 1080 N (242 lbs) |

| Pad Stroke Adjustment | +/- 10mm |

| Plate/Cliché Size | 100 x 215 mm |

| Ink Cup | Mechanical: SpaceFrame with ExpressLiners OR Magnetic: MCI Ink Cup |

| Ink Cup Size | 90 mm |

| Maximum Print Size | 80 mm |

| Voltage | Single Phase 230 V 50/60 Hz |

| Control Voltage | 24 V |

| Power Consumption | app. 500 W |

| Controls | Siemens PLC with Touchscreen User Interface |

| Number of Recipes | 20 |

| Machine Dimensions (W x L x H) | 325x850x810 mm (without pad cleaning) 480x850x810 mm (with pad cleaning) |

| Weight | app. 140 kg (300 lbs) |

| Languages | English, Spanish, German, French |

OSHA requires systems to prevent operators from reaching the point of operation when the machine is running. Trans Tech offers three standard safety packages for stand-alone operation of our standard pad printers.

| Safety Package Comparison | |||

| Covers | Operator Runs System By | System De-Energizes When | |

Full Guard Package |

Hard guarding covering the entire system and safety light curtains. | Using an external safety touch button. | Operator loads and unloads parts or when the operator interfaces with machine’s user interface. |

Small Guard Package |

Hard guarding covering the part handing area and safety light curtains. | Using an external safety touch button. | Operator loads and unloads parts. |

Two-hand Anti-Tie Down Package |

Package consists of two safety touch buttons. | Placing fingers from both hands on the safety touch buttons. | Operator removes a finger from one of the safety touch buttons. |

Resources

Instructional Videos

Pad Printing 101

| Product Comparison | |

| SealCup Express | |

| Cycle Speed | Up to 3600 cycles/hour |

| Drive | Electromechanical |

| Max Compression | 1080 N (242 lbs) |

| Plate/Cliché Size | 100 x 215 mm |

| Pad Stroke Adjustment | +/- 10mm |

| Ink Cup | Mechanical: SpaceFrame with ExpressLiners OR Magnetic: MCI Ink Cup |

| Ink Cup Size | 90 mm |

| Weight | app. 140 kg (300 lbs) |

| Maximum Print Size | 80 mm |

| Number of Recipes | 20 |

| Machine Dimensions (W x L x H) | 325x850x810 mm (without pad cleaning) 480x850x810 mm (with pad cleaning) |

| Air Consumption | N/A |